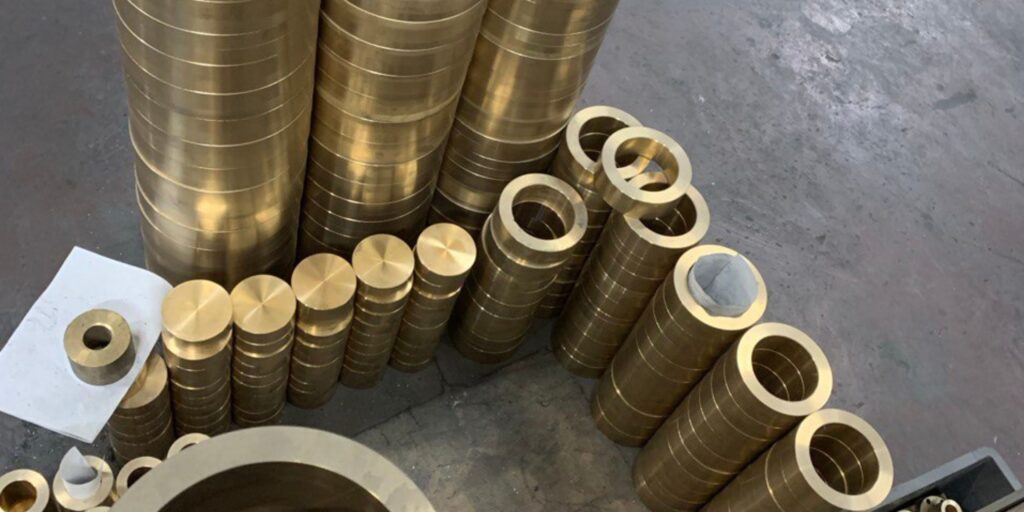

Bronze bushings are sliding bearings that are used in the manufacture of various industrial equipment – excavators, tractors, dump trucks, presses, pumps, mining equipment.

Bronze Bushing Features:

Areas of application:

- Resistant to heavy loads as well as mechanical loads.

- Decent anti-corrosion properties.

- Plasticity and high material density.

- Optimal electrical conductivity index.

- The ability to work in conditions of high humidity and sudden changes in temperature.

Bronze bushings are used in a variety of applications. They are used in mechanical engineering, construction of machine tools, mining, railway construction, for the production of various types of equipment, hydraulic presses. The use of such products reduces the risk of an accident, increasing the reliability of the mechanism.

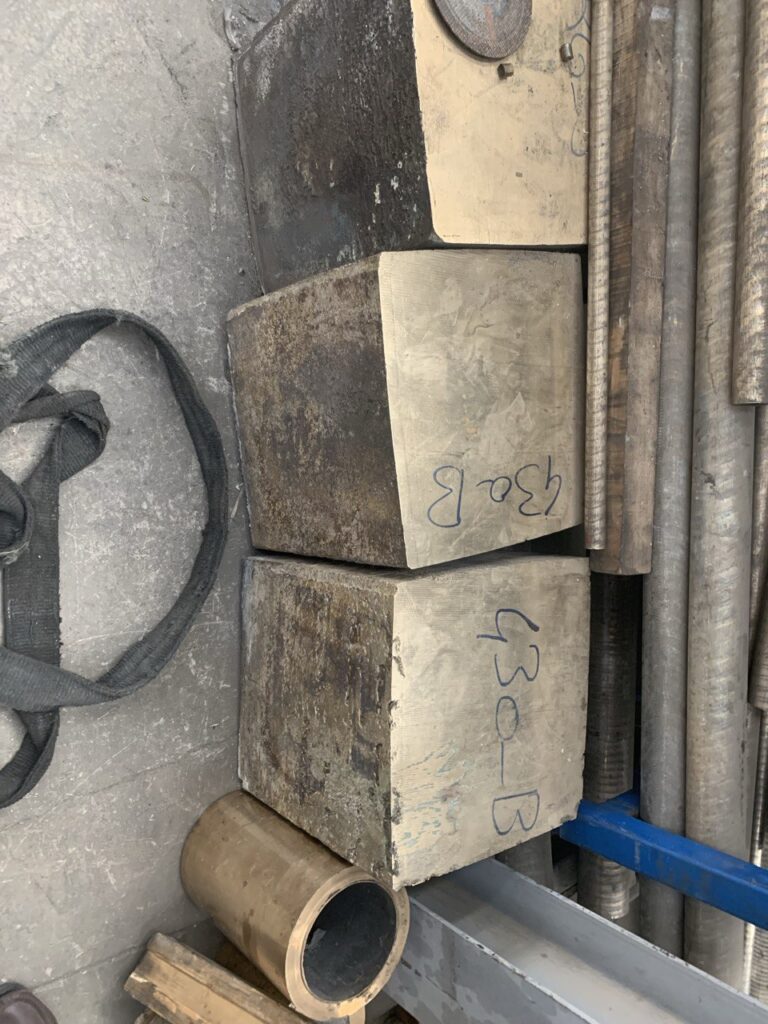

The bushings are produced in the following grades.

Species

PN

DIN

B101

B555

BA1054

BA83

BA1032

RG7

CuSn10P

CuSn5Zn5Pb5

CuAl10Ni5Fe4

CuAl8Fe3

CuAl10Fe3Mn2

CuSn7Zn4Pb7

* And other grades on request

Production methods:

Currently, bronze bushings are produced in several ways: the main ones are die casting and centrifugal casting, as well as sand casting.

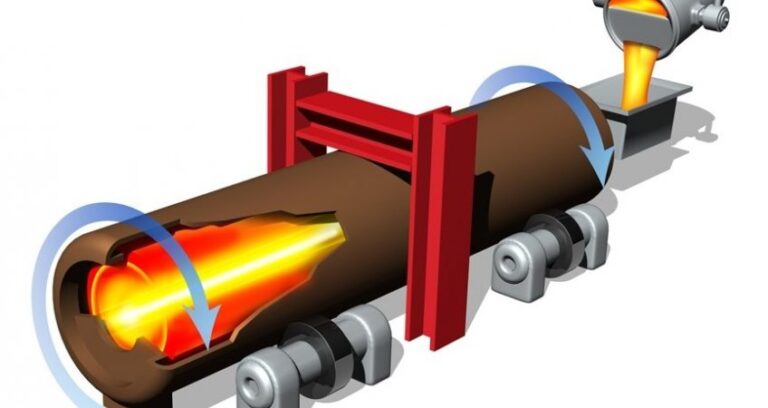

Centrifugal casting

The most advanced and sought-after method of manufacturing bronze bushings is the centrifugal casting method, which enables obtaining a product of high density (especially in the outer layers), without air pockets. Currently, about 60% of products are made in this way.

According to this technology, the alloy is poured into a rapidly rotating mold in a vertical or horizontal plane, and its crystallization takes place under high pressure. Such products have optimal mechanical properties and require minimal allowances for further processing, which allows to reduce the cost of the finished product.

Casting of bronze sleeves in chill molds

The second most popular method is cold casting – in a special detachable mould. After the metal has solidified and cooled, the cooling mold is opened and the finished product is removed from it. The main disadvantage of this method is that the mold is filled with liquid alloy and the product solidifies only under the influence of gravity, without external pressure. Therefore, the density and mechanical properties of the product are lower than its centrifugal-cast counterpart. The advantages of pressure casting include the ability to produce products with complex shapes and large dimensions (up to 1500 kg).

If in the production process bronze bushings are cast by centrifugal casting, this implies further processing of the part. Die casting of bronze bushings is suitable for bushings with a complex design. Sand casting is used in the production of large diameter parts, while bronze bushings range in size from a few centimeters to over a meter.

Alloy Metal manufactures bronze elements. Production is carried out in several ways – centrifugal casting, casting in chill molds. Products are manufactured both according to customer drawings and in standard dimensions. It is possible to order bronze bushings with pre-treatment or complete processing according to drawings provided by the customer.

You can order bronze bushings from us. Our foundry can produce bronze bushings up to 900 mm in diameter and up to 800 mm in length

We will be happy to answer any questions by phone: +48 221 228 646

The bronze bushing is a consumable, a cylindrical part that is used in machines and mechanisms that are subjected to constant loads. Depending on the purpose of the bronze bushing, there are mounting, bearing, transition and other bushings. They are used in the chemical, light and heavy industry, as well as in various fields of mechanical engineering (for example, in nodes of mining excavators).

Currently, they are one of the most popular and sought after bronze products. Due to the high quality of the products, valuable physical and chemical properties, high strength, bronze bushings can be used in mechanisms that are exposed to heavy loads.

The use of a bronze sleeve

The classic application of the z-sleeve is the role of a plain bearing. This is necessary for industrial equipment such as:

- turbine;

- pump;

- machine tool;

- reducer;

- rolling mill;

- generator.

The service life depends on the type of bronze used in production. Some properties can also be affected by which elements are present in the material, as bronze can be:

- tin;

- aluminum;

- silica;

- beryllium.

Bushings are often used in anti-friction parts, fittings and various nuts. They are chosen when you have to work in water – such an environment will not harm bronze products, which is why they are ideal for pumps.

In the metallurgical and mining industries, sleeves are essential for cone crushers. These devices require highly wear-resistant parts, and that’s what bronze provides. They are also needed in the manufacture of stamping and pressing equipment. Bronze bushings are also typically used in excavators – these products are excellent as linings and washers.

What are the advantages of bronze bushings?

All these advantages are due to the properties of the material itself.

- Low adhesion. It is this factor that provides the anti-friction properties of the material during friction.

- High thermal conductivity and heat capacity. The thermal conductivity of bronze is 16-260 W/(m∙K) depending on its type. Melting point – 854 to 1135°C. These indicators contribute to the formation of layers that reduce friction.

- Stability of mechanical properties. Bronze bushings guarantee a long service life without the need for repair or replacement of parts.

Good compatibility with chrome and steel parts, high wear resistance and thermal conductivity ensure the popularity of this product in various fields of mechanical engineering and instrumentation. With a simple setup, bronze bushings can be easily changed without significant investment in repair work.

We will be happy to answer any questions.

We will contact you within one working day.

Telephone:

+48 221 228 646

Address:

st. Warsa i Sawy 11E, 05-840, Domaniew